INTERPRETING 2D DIC DATA

Why does my strain or displacement data not match theory or other measuring techniques?

INTRODUCTION

Digital Image Correlation (DIC) data is often used as a validation method, so being able to compare DIC data to theory, FEA analysis, strain gauge measurements, or other techniques is important. When comparing data, it’s important to consider the following:

-

DIC measures surface strains of continuous materials

-

Vic-2D provides local and global strain data with various strain variable and tensor options

-

Test set-up can affect data

-

There are many causes of noise and bias in DIC results (and many ways to eliminate these causes)

DIC IS A 2D SURFACE TECHNIQUE FOR A CONTINUOUS SURFACE

Standard DIC techniques only use images of the surface of a material. This means the only information available is from the surface, and therefore results are only relevant to the surface behavior of the specimen.

Additionally, because of how we track and match images in order to obtain data, and because of the fundamentals of strain theory, we must treat the area of interest as a continuous surface. Discontinuous surfaces can result in unreliable data and erroneous strains.

For more on Continuous Surfaces in DIC, please refer to the application Note:

Continuous Surfaces in DIC

Discrepancies can sometimes arise due to behavior of the specimen that interrupts the ability of DIC to track a specimen’s deformation.

-

Cracks or holes in the specimen are typically removed from results because once a material breaks apart because it is not strained across the hole/crack any longer. Any attempt to use subset size and thresholding to bring this data back into the contour plot will result in erroneous strain data.

-

Some materials such as composites, textiles, and biological tissues that have micro-structure can behave continuously on a macro level but then have fibers slipping past each other or other discontinuities on a smaller level. This could produce erroneous strains as well.

INTERPRETING STRAINS IN VIC-2D

Comparing local and global strains

When comparing strains from Vic with those from strain gauges or other similar techniques, it is important to note that Vic reports a full-field contour plot of strains at individual points, whereas strain gauges report strain over the length of the gauge. To analyze global strains, you may use inspector tools, like “Inspect rectangle” and extract the average strain value within that rectangle through “Plot extractions”. When comparing strain gauge/extensomer data, you may use the inspector tools to place a extensometer on either end of the gauge that you are comparing it to and again “Plot extractions,” and then select “extensometers” in the drop down menu that you’ll see on the upper left of the screen.

Also note that the size of each individual virtual strain gauge on the contour plot is controlled by both the step size and filter. The localized virtual strain gauge size is the step size x strain filter. For more explanation on interpreting local/global data and strain filter selections, please refer to the application note:

Strain Filter Selection

Strain tensor types

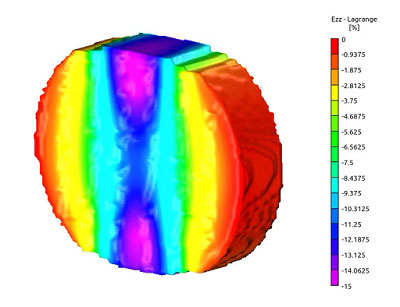

To compare strain values obtained from DIC to results from other methods, it is important to compare the same strain tensor type. By default, Vic-2D reports strain as Lagrange strain, but the strain tensor can be selected at run-time in the postprocessing tab or during the strain calculation dialogue. There are many strain tensors available in Vic-2D. For more information on different strain tensor options, please refer to the application note:

Strain Tensors and Criteria in VIC

Below are a few things to consider if your DIC data is not as predicted by strain gauges or theory:

-

Engineering strain should be selected in the strain calculation dialog in order to compare data from strain gauges/extensometers, etc.

-

If you notice that the strains you are comparing match well at low strains and deviate at high strains, you are likely comparing Lagrange strain to Engineering strain. (At large strains, Lagrange strain can become much larger than Engineering strain due to the higher order term.)

-

If you notice that your shear strain is off by a factor of 2, you are likely comparing Lagrange strain to Engineering strain. (Lagrange shear strain is equal to half the Engineering shear strain.)

Strain Variables and Consistency of Coordinate Systems

Strains reported in Vic are given in terms of exx (strain along the X axis), eyy (strain along the Y axis), exy (shear strain), e1 (major/first principal) and e2 (minor/second principal), gamma (major strain angle, the angle between the positive x-axis and major strain axis). It is important to consider the different strain variables when comparing strain data.

The x and y axis will align with the camera sensor. So test setup/aligning the camera to the specimen is important, if you wish to investigate exx and eyy strains.

If you are interested in comparing major and minor strains, it may be helpful to visualize the major and minor directions. The major and minor strain directions can be displayed on the contour plot by using the tools in the “Vector” tab of the "Plotting Tools" menu.

TROUBLESHOOTING TEST SETUP

Out-of-plane motion in Vic-2D

For Vic-2D only, out-of-plane motion of the specimen reported as erroneous strain. With only one camera, there is no way to differentiate between a surface appearing larger because it gets closer to the camera and the surface actually straining. For this reason, 2D test should be very careful to avoid out-of-plane motion. Some suggestions include using a longer stand-off distance so any motion is less significant and keeping the specimen as planar to the camera as possible. (The strain error due to out-of-plane motion is equal to the amount of out-of-plane motion divided by the standoff distance between the lens and specimen.)

Tilt of specimen

The specimen must be planar to the camera sensor in Vic-2D. If it is tilted, then erroneous strains will be present.

Specimen Geometry

The specimen must be flat for Vic-2D applications. Any non-flat geometry will product erroneous strains in the data.

Lens Distortion

Since Vic-2D cannot calibrate distortion, it is recommended that long, low distortion lenses are used. Shorter lenses and cheaper lenses will produce more distortions. There is a procedure to remove the distortions, if they are unavoidable. See section “Viewing through a Windows” for link to the 2D distortion correction.

Heatwaves

The presence of heatwaves can cause bands of false displacement and strain to appear in results. The bands typically move from image to image, and may or may not result in error in Vic-2D. Try to eliminate heatwaves by placing any hot lights above or behind the cameras, using cool light sources such as LEDs, or using a fan to mix the air around the specimen and optical path. If it is impossible to eliminate the heatwaves, time averaging results can mitigate the bias. For more on heatwaves, please refer here:

Heat Waves in DIC

Motion blur

If exposure times are too long during dynamic testing, motion blur can cause projection error. If this is suspected, reduce exposure times as necessary. Ideally, exposure time is selected to keep motions below approximately 0.01 pixel during the exposure.

Debris

Contaminations (e.g. dust on camera sensor) can cause large, localized bias in displacements and strains. These cannot be mitigated through processing, and must be dealt with prior to imaging.

Visible strain gauges

When using DIC and strain gauges at the same time, it is likely that the strain gauge will be visible where the cameras are imaging. Even if the gauge is painted over with the speckle pattern, any slipping between the gauge or gauge connections/tape and surface that occurs will result in the DIC results being inaccurate. Remember that DIC must assume a continuous surface. So it is necessary to analyze a location which is not obstructed by the gauge (likely, just adjacent to the gauge).

Alignment of Test Fixture

Comparing exx and eyy with principal strains can indicate that there might be misalignment in the setup, or some torsion introduced in the test, is. If theory predicts pure tension and these strains do not match (after you investigate the coordinate system to make sure the coordinate axis lines up with the load axis), it is likely that there is something going on in the test set-up that is causing this.

Slippage of Specimen within Test Fixture

If the specimen slips within the test fixture, it will likely not strain as predicted by theory. Often times, a specimen will slip in tensile tester grips, for example. If this occurs, it can slip in the beginning of the test and then catch within the grips and strain for the rest of the test, or it can strain as predicted, then slip at higher loads. This is something to be mindful of.

Viewing through windows

It is sometimes necessary to view specimen through a glass window pane or other medium that causes distortions. If viewing through a window, you will likely need to use a distortion correction calibration.

Speckle Pattern Slipping on Surface or Degrading in Test Conditions

It is imperative that the speckle pattern does not slip on the surface of the specimen. It must deform with the surface that is being tested. It is also imperative that the speckle pattern holds up to test conditions (does not melt in heated tests, does not lose speckles due to the event being dynamic, must not lose speckles due to the test being in water or being exposed to convection, does not crack before the surface does, etc.).

NOISE AND BIAS IN DIC DATA

It is possible that calibration, test set-up, or other conditions can introduce bias and increase noise into the results from DIC. To help identify and reduce noise and eliminate bias, consider the following common causes and how to correct them.

Bias in 2D DIC Data

With the proper test setup, bias should be eliminated from results. The following can introduce bias into Vic-2D results:

-

Viewing through a window

-

Lenses with high distortion (short lenses or inexpensive lenses)

-

Out-of-plane motion: any out of plane motion will be computed as strain in Vic-2D

Noise in 2D DIC Data

In some situations, especially when looking at very small strains, high noise levels may make it difficult to get good results. As with all measuring techniques, noise is not avoidable in DIC, but steps can be taken to minimize it.

Preparation of the specimen and setup are the most important factors to reducing noise. The following can increase the noise in DIC data:

-

Images processing in third party software (this is never beneficial):

Processing Images for DIC Analysis

-

High signal-to-noise ratio: Color images, or noisy sensors will increase strain noise.

-

Blur/Defocus

-

Poor Contrast/Lighting

-

Glare

-

Heatwaves: Can even come from lights being used

-

Low F-stop: Images can be diffraction limited

-

Good speckle pattern